Co-design

Internally, a team accompanies you from the preliminary project to the industrialization of your parts in series: analysis of the best technical solution, economic optimization, productivity gains. Our permanent watch on innovative processes, our technical culture and the experience we have acquired in many sectors of activity are beneficial to you!

Design of 3D drawings, CAD (use of SolidWorks allowing formats compatible with the major CAD standards)

Logistics

With 1 million parts delivered per year, Nourrisson Tunisie ensures optimal shipment of your parts worldwide. Thanks to a personalized service, all your requirements regarding your needs and products are taken into account:

Studies of shipping solutions

Packaging solution studies

Implementation

Consignment stocks

Our information system, directly linked to yours, allows you to follow in real time the shipments made.

Control of the supply chain: :

- safety stock

- consignment stock

- delivery to order

- deported stock at our suppliers

- pull flow

- control of our suppliers

- WEB EDI

- transport management

- management of specific packaging

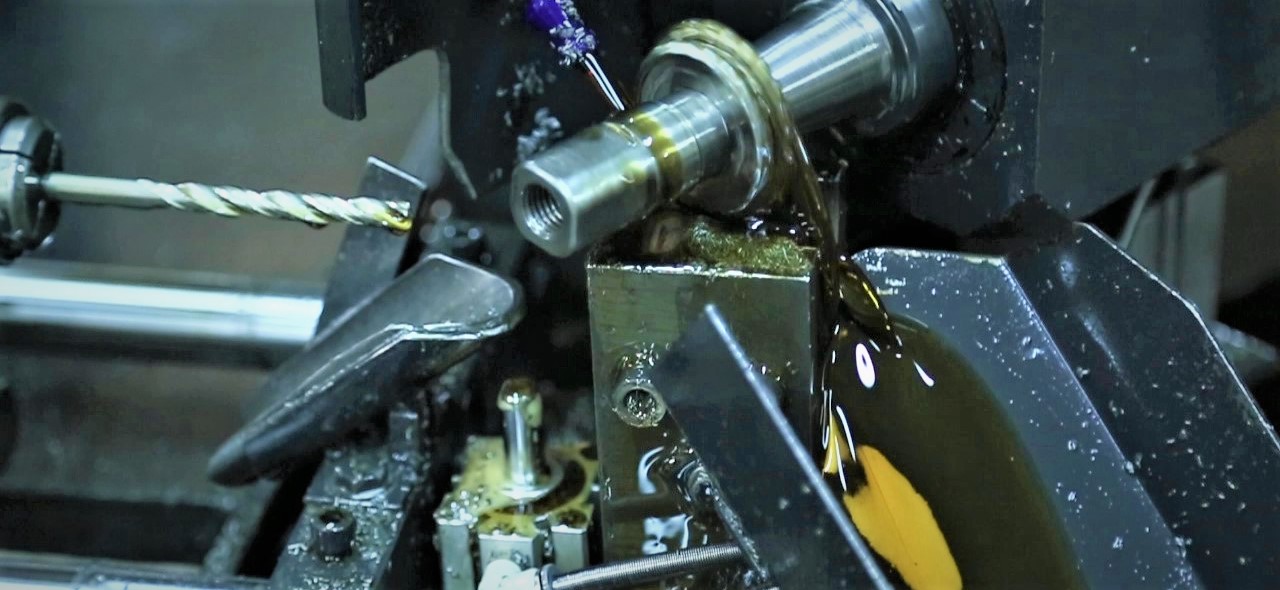

Bar turning

With our multi-spindle and single-spindle turning machines we are able to machine from diameter 3.5 to 65.

Drilling

Special drilling for all types of chucks and manual drilling of nuts.

Turning

With our universal machines and our 2-axis and 3-axis numerical control machines we are able to do all types of turning.

Milling

Especially automatic milling for all types of jaws.

Threading

We are able to make special tapered threads used for nuts and drill tips.

Also we make the threading of jaws for different diameters and pitches.

Assembling and packing

Manual or automatic assembly with press And packaging of any product manufactured in-house whether vacuum or manual.

Ability to perform precision manual tasks

Assembly of manual parts, grinding of parts, polishing,...

Knurling

Knurling of parts made of sheet metal or steel for different diameters.

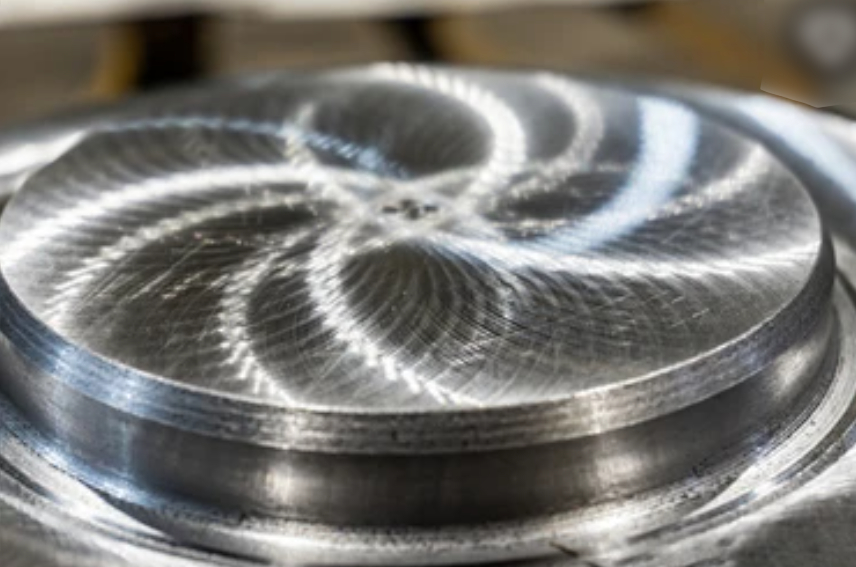

Hobbing

Cutting of all types of wood and concrete drills with special CNC cutting machines.

Cutting of steel chuck liners and curvilinear or oblique teeth for plates and files.

Finishing treatment

We outsource surface treatments such as:

Zinc, Zinc Nickel, Anodizing, Hard chrome, Burnishing, Tribo-finishing, Sandblasting, Nickel plating, Stainless steel passivation, etc.

And also heat treatments such as:

HF quenching, Carbonitruration, Quenching +tempering, etc.

Heat treatment

Quenching and tempering, surface quenching, HF quenching, induction quenching, cementation, nitrocarburation, carbonitruration, annealing.

Surface treatment

All types of zinc plating, nickel plating, silver plating, chrome plating, anodizing, hard anodizing, burnishing, painting, varnishing, phosphating, ...